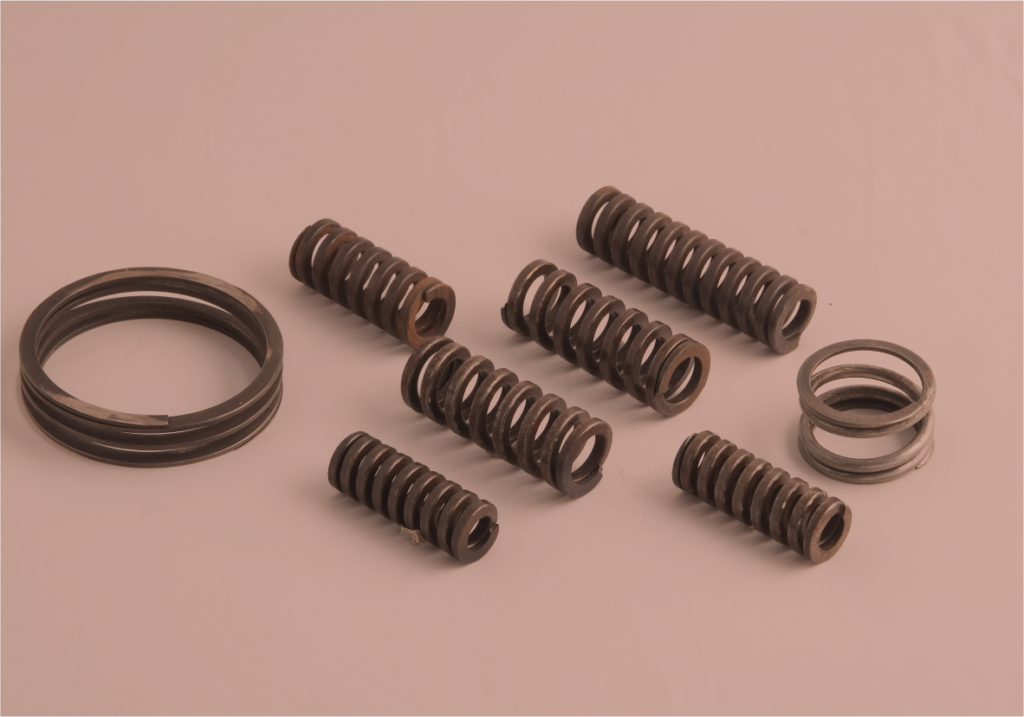

DIE SPRING

Overview

Die springs also known as high force compression springs. These springs are designed to maintain & withstand great levels of applied stress. They can handle 30% more stress than a standard compression spring & are also beneficial in extreme & stressful environments, even handling temperatures rising to 475 degrees. Made from rectangular or square wire, Die springs have a number of unique qualities, the first being the material they are made from. The use of rectangular and square wire is the prime element that gives the die spring its unique property, and it is this larger mass which provides the spring with a greater force. The springs are stress relieved after coiling, pre-set and shot peened to provide maximum fatigue life. Both ends are precision ground and then powder coated with a solid colour, each group of Die Springs is divided into a rising load range & can be identified by colour coding system.

Material

- Die Springs or High Force Compression Springs are made of pre-tempered, rectangular shaped chrome silicon wire.

- Chrome Silicon ASTM A 401

Manufacturing Process

Die Springs are manufactured on imported CNC Spring Coiling Machines with SPC on line with free length sorting device for critical load value.

Testing & Certification Process

Each spring manufactured goes through a series of rigorous tests conducted on in house testing facilities such as Computerized Load Testing, UTS Testing, Torsion testing, Profile Projector amongst others. All springs are supplied with ROHS raw material compliant report. We also provide PPAP documents for automobiles and electrical industries as per requirement.

PRODUCT APPLICATIONS

Clutches & brakes in the Automotive Industry, Transportation Industry, Agricultural industry, Oil & Gas Drills, Aircraft Mechanics, various types of Moulds.

RELATED PRODUCTS

COMPRESSION SPRING

Compression Springs are designed to operate with a compressive load in “Push Mode”. Compression Spring also has variable pitch between coils which are used to reduce solid height, buckling and surging to produce nonlinear load deflection characteristics.

GARTER SPRING

Garter springs are essentially helical springs with connected ends; it forms a circle to provide a strong radial force. Garter springs are basically extension springs or compression springs whose ends are connected to make a garter belt that will exert force from its inner diameter.

TENSION SPRING

Tension Springs/Extension Springs are helical wound coils, wrapped tightly together to create tension. Extension springs are springs which absorb and store energy by offering resistance to a pulling force.

SPIRAL SPRING

Spiral springs also known as constant force spring or Clock spring. This type of spring is usually a coiled ribbon of spring steel used for functions such as counter balancing, retrieving, maintaining constant loads, transmitting motion, and clamping. It requires nearly the same force, no matter how long the extension.

TORSION SPRING

Torsion Springs / Helical Coils Springs are designed to operate with torque / twisting / rotary force. A torsion spring is a spring that works by twisting its end along its axis. When it is twisted, it exerts a torque in the opposite direction, proportional to the amount (angle) it is twisted.

CONICAL SPRING

Conical springs are compression springs which are helically coiled round wires forming a tapered or conical shape. They are used to provide balance & reduce the solid height by the coils telescoping into each other. Conical springs are basically compression springs coiled in increasing or decreasing outer diameters thus making its shape a cone or tapered one.

CLUTCH SPRING

Clutch springs can be found in use on most motorcycle clutch assemblies. The function of these short coil springs is to continuously hold the friction & driven plates together through spring tension, preventing slippage except when the clutch lever is engaged.

WIREFORMS

Wire forms come in all sorts of shapes & sizes and each play different role. Wire forms are wires that have been bent into specific shapes, often to fulfil a particular purpose, one can commonly recognize wire form as a spring; though any shape that a wire takes is technically a wire form, other often seen wire forms include hooks and certain types of clips.

SHEET METAL COMPONENTS

Sheet metal is available in flat pieces or coiled strips. The coils are formed by running a continuous sheet of metal through a roll slitter. Sheet metal is one of the fundamental forms used in metalworking, and it can be cut, bent and formed into a variety of shapes.